Plant Utility Control & Monitoring

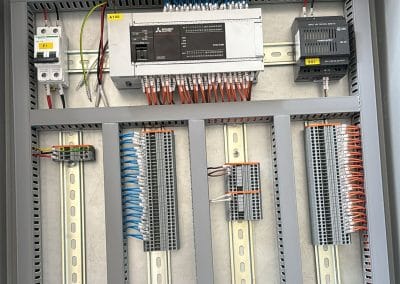

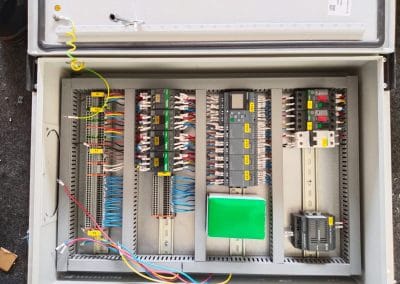

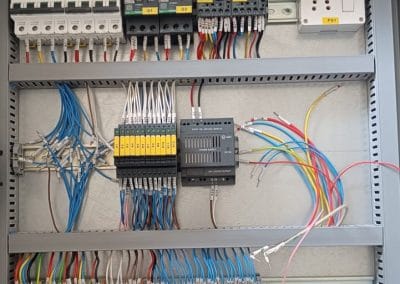

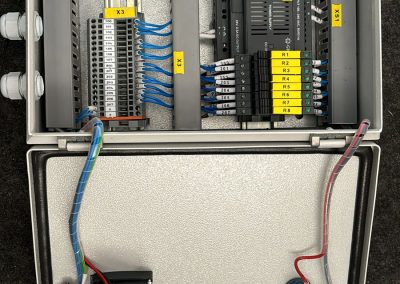

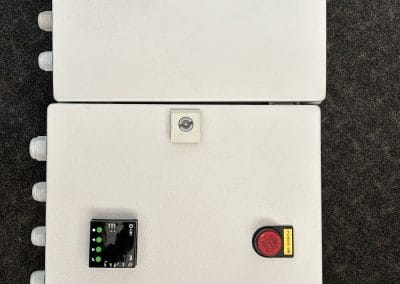

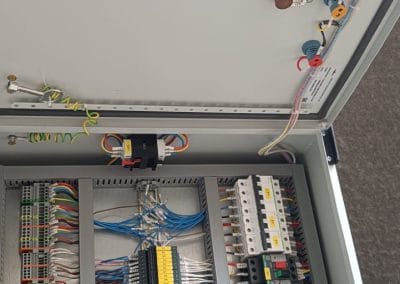

Effective plant utility control begins with real-time monitoring of utility systems. This involves using sensors and control systems to track usage, performance, and potential issues. For example, monitoring systems can detect fluctuations in energy consumption or water flow, which can indicate inefficiencies or equipment malfunctions. By identifying these issues early, plant operators can address them promptly, minimizing downtime and operational disruptions.

Overall, effective plant utility control and monitoring help ensure that a plant operates efficiently, reduces operational costs, and maintains a reliable supply of essential utilities. By leveraging advanced monitoring technologies and proactive management strategies, plants can enhance their operational performance and sustainability.

Related Works