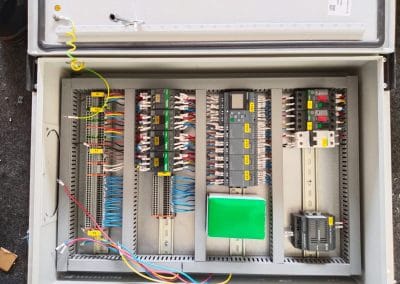

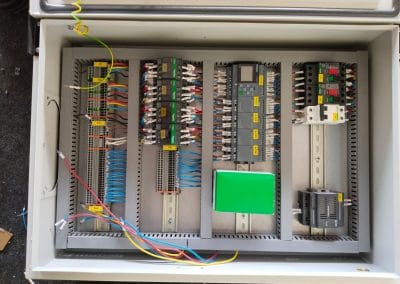

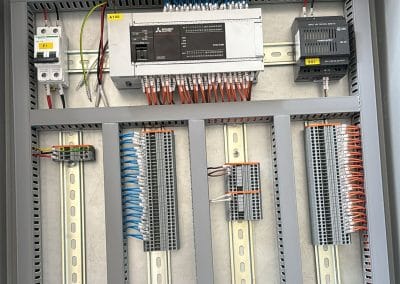

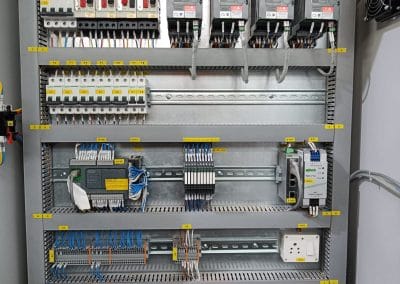

MCC & PCC CONTROL PANEL

MCC & PCC CONTROL PANEL

Salient features of Our MCC/PCC panels

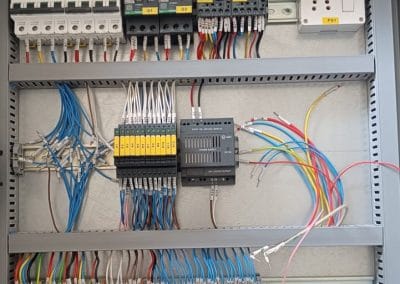

| Reliability: | Panels are designed to ensure continuous operation with minimal downtime. High-quality components are used for longevity and reliability. |

| Safety Standards: | Compliance regulations at par with national and international safety standards (such as IEC, NEC, or NEMA) is ensured for safe operation and protection of personnel and equipment. |

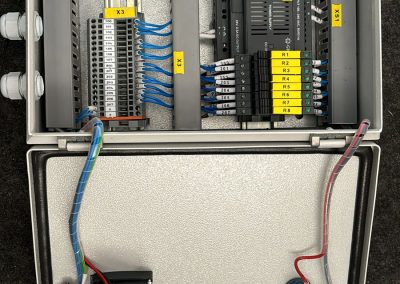

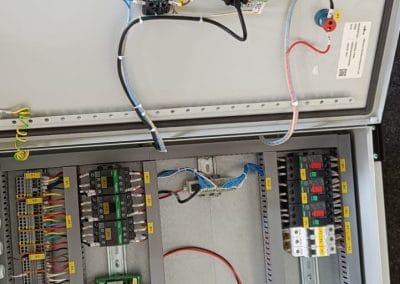

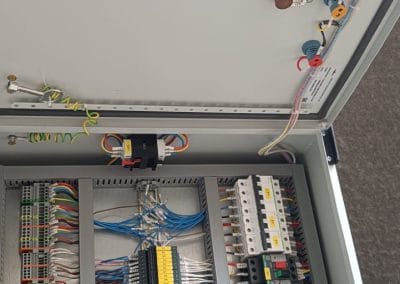

| Ease of Maintenance: | Panels are designed to provide easy access to components for maintenance, repairs, and inspections, minimizing downtime and operational disruptions. |

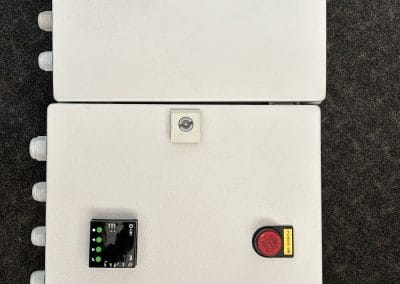

| Durability: | Constructed with robust materials to withstand harsh environments (temperature variations, humidity, dust, etc.), enhancing the lifespan of the equipment. |

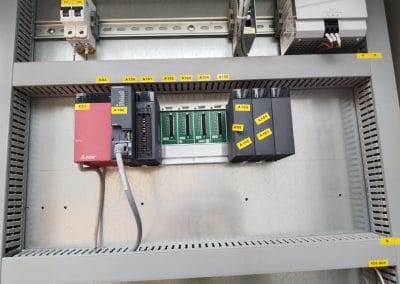

| Scalability: | The capacity to easily upgrade and expand the system as business needs change without requiring a complete redesign. |

| User-Friendly Interface: | Clear labeling and ease of use for operators, often incorporating Human-Machine Interfaces (HMI) for monitoring and control. |

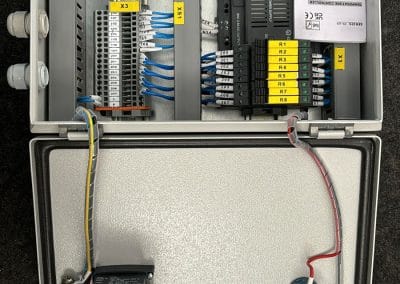

| Flexibility: | Adaptability to accommodate various configurations and applications, including different motor types, power ratings, and control functions. |

Know this Before ordering

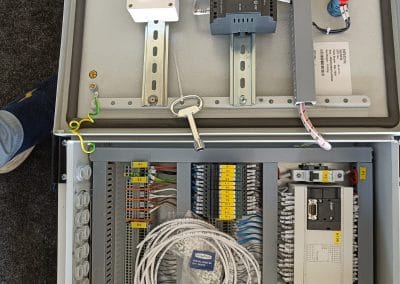

| Busbar Rating: | Determining the current-carrying capability of the busbars (usually rated in Amperes) for reliable power distribution. |

| Enclosure Type: | Typically rated IP (Ingress Protection) or NEMA (National Electrical Manufacturers Association) ratings for environmental protection (dust, moisture, etc.). |

| Voltage Rating: | Specifications for the maximum operating voltage the panel can handle (e.g., 415V, 690V). |

| Current Rating: | Maximum current rating for the panel, which must match the load requirements. |

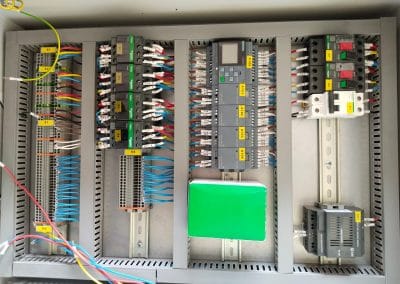

| Control Components: | Types of control devices included (e.g., contactors, overload relays, variable frequency drives) that ensure the effective management of motor operations. |

| Protection Features: | Inclusion of circuit breakers and fuses for overcurrent protection, as well as other protective devices (like earth fault protection). |

| Communication Protocols: | Support for various communication protocols (e.g., Modbus, Profibus, Ethernet/IP) for integration with building management systems or SCADA (Supervisory Control and Data Acquisition) systems. |

| Thermal Management: | Features for heat dissipation, such as ventilation or cooling systems, to keep temperatures within safe operating limits. |

| Fault Monitoring and Control: | Advanced features for fault detection, diagnostics, and logging to facilitate quick identification and resolution of issues. |

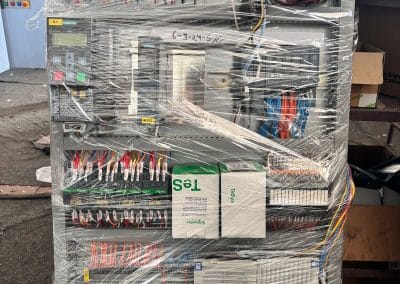

| Testing and Certification: | Certifications from recognized institutions indicating compliance with applicable standards (e.g., UL, ISO, etc.), ensuring quality and safety. |

| Conclusion | Choosing the right MCC/PCC panel involves evaluating these qualities and specifications to ensure they meet the specific needs of your facility, processes, and equipment. A well-designed and engineered panel will improve operational efficiency, safety, and reliability in electrical power control and distribution. |

Related Works