Pick & Place Systems

Pick & Place Systems

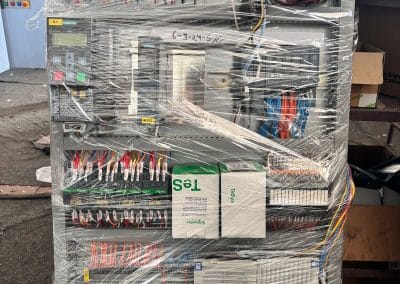

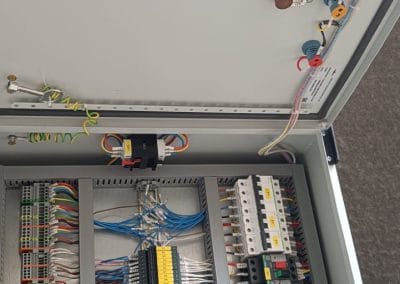

Pick & place systems are a cornerstone of modern manufacturing and assembly processes. These automated systems streamline operations by picking up items from one location and placing them in another with precision and speed. Ideal for industries ranging from electronics to food processing, pick & place systems enhance efficiency and consistency in production lines.

At the heart of a pick & place system is a robotic arm or automated machine equipped with a gripper or suction device. These systems are programmed to handle various tasks, such as sorting, assembling, and packaging. Their adaptability allows them to manage different product sizes and shapes, making them highly versatile.

One of the key advantages of pick & place systems is their ability to operate continuously with minimal human intervention. This not only reduces labour costs but also increases productivity and reduces the risk of errors. By integrating sensors and advanced control systems, these machines ensure that each item is handled accurately and efficiently.

Overall, pick & place systems are essential for optimizing manufacturing processes. They offer a reliable solution for boosting output, maintaining quality, and staying competitive in today’s fast-paced market. Whether you’re scaling up production or seeking to improve workflow, investing in pick & place technology can deliver significant benefits.

Related Works