Orientation Checker

Orientation Checker

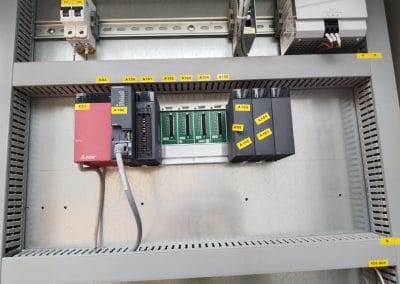

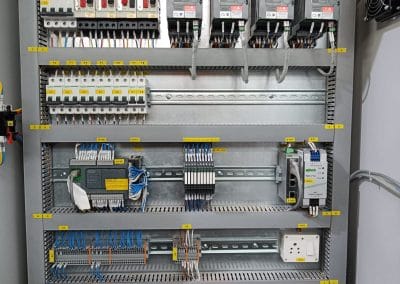

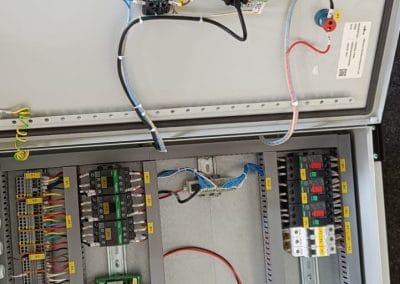

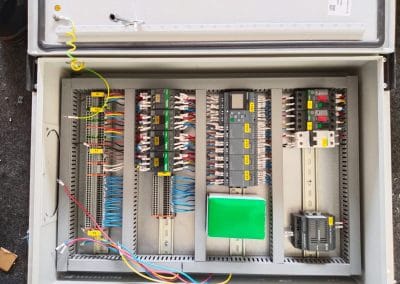

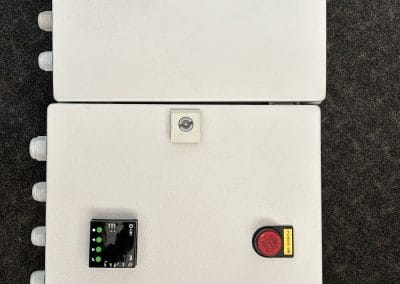

An Orientation Checker is a crucial tool used in various industries to ensure that products, components, or assemblies are correctly aligned and oriented according to specified standards. This device plays a vital role in quality control and production processes, helping to prevent errors that could lead to faulty products or operational inefficiencies.

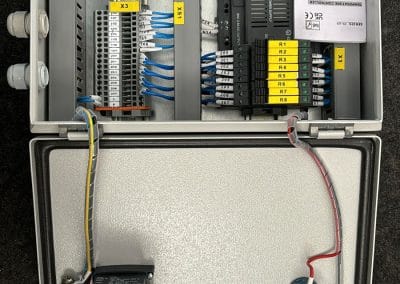

The primary function of an Orientation Checker is to verify the alignment and orientation of objects during manufacturing or assembly. It checks whether parts are positioned correctly, ensuring that they meet design specifications and functional requirements. This helps in maintaining high-quality standards and reducing the risk of defects.

Typically, Orientation Checkers are equipped with sensors and measurement systems that accurately detect deviations from the desired orientation. They provide real-time feedback, allowing operators to make necessary adjustments promptly. This helps in minimizing downtime and improving overall production efficiency.

In addition to manufacturing, Orientation Checkers are also used in sectors like electronics, automotive, and aerospace, where precision and alignment are critical. By using an Orientation Checker, companies can enhance product reliability, reduce rework, and ensure that components fit together seamlessly, ultimately leading to higher customer satisfaction and reduced operational costs.

Related Works